SOAR Vending

SOAR Vending is developing a vending machine that will dispense workout supplements in fitness centers. My capstone team designed a new storage system and dispenser that was both accurate and compatible with different powders.

After initial brainstorming, the team decided to pursue two different mechanisms. The first prototype utilized compressed air to fluidize the powder and allow it to constantly flow. Air is directed through various channels through the yellow, black, orange, and red parts. A linear actuator (green) pushes up a cone valve (blue) to begin dispensing.

Powder Fluidization

The powder fluidization prototype was able to properly dispense lighter powders, but struggled with heavier, sticker powders. The design was intended to be used with 12 different hoppers, however, the air channels experienced clogging and powder saltation which would lead to issues with cross contamination. Because of these issues, the team decided to ultimately abandon the idea.

Powder Fluidization Prototype

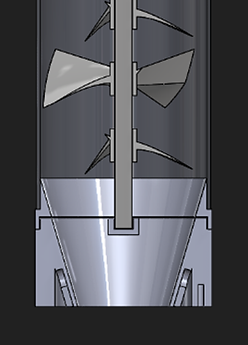

The second prototype was based off a flour sifter, using vertically stacked blades and a wire-mesh dispense powder. A hex axle running through the entire hopper turns the fans, lifting the powder up to agitate the powder. The bottommost fan is orientated in the opposite direction in order to push powder through the mesh. Blade geometry was determined from powder flowability experiments, which determined the angle of repose. Vibration motors in the bottom funnel move any powders clinging to the inner surface downwards.

The axle is secured by a bearing in the lid and extends outwards so that a singular motor and gear system could drive 12 different hoppers. There are also compartments for desiccants to control the humidity and keep the powders dry.

Mixing Blade Bottom

Mixing Blade Top

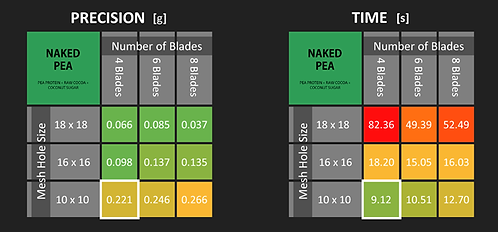

Different configurations were tested for each powder. The optimal configuration was determined by using heat maps of the data. The clients specified that they wanted the system to dispense a 30 gram serving in under 30 seconds, within a 1 gram margin. The prototype was able to dispense 30 grams in under 10 seconds within 0.5 grams.

Naked Pea Optimization Heat Map

Final Prototype

Capstone Day Poster